Safety Performance 55

Maintaining the integrity of our pipeline network

is crucial to business success. We pay great

attention to strengthening our trench inspections

and have undertaken more in-depth leakage

surveys while upgrading ageing pipes. In addition,

our sophisticated Supervisory Control and Data

Acquisition system (SCADA) allows us to monitor

and control more than 3,500 real-time telemetry

points. This helps our entire network, including

every strategic pressure-regulating station,

to operate smoothly. If an incident does occur,

our remote control, emergency logging and

geographical information systems will enable us

to respond quickly, efficiently and accurately. In

2016, we carried out 176,925 inspections at 12,606

sites, and surveyed 6,817 km of pipeline.

Network Safety

Further efforts to improve safety include Quality

Testing Services Limited, our wholly-owned

subsidiary, which is accredited under the

Hong Kong Laboratory Accreditation Scheme

(HOKLAS) for gas meter collaboration services,

gas appliance testing, stainless steel gas tubing

and PE fitting. Another is our Pay For Safety,

Quality and Environmental Appraisal System,

which recommends that contractors ask their

staff to demonstrate responsible awareness when

working on pipe-laying contracts. If specified

criteria are met, contractors receive a bonus of

1% to 2% of the contract sum. Schemes such as

this are not new in Hong Kong, but our system is

unique because 50% of the incentive total is paid

directly to frontline workers.

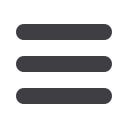

Network Safety Performance 2016

Leakage and Pipeline Surveys

Area

Results

Target

Gas Supply Reliability

99.991%

>

99.99%

Gas Incidents Reported by the Public per 10 km of Gas Pipes

0.18

<=

0.15

Third-party Damage Incidents

13

<=

7

Emergency Team Average Arrival Time within 25 minutes

Achieved

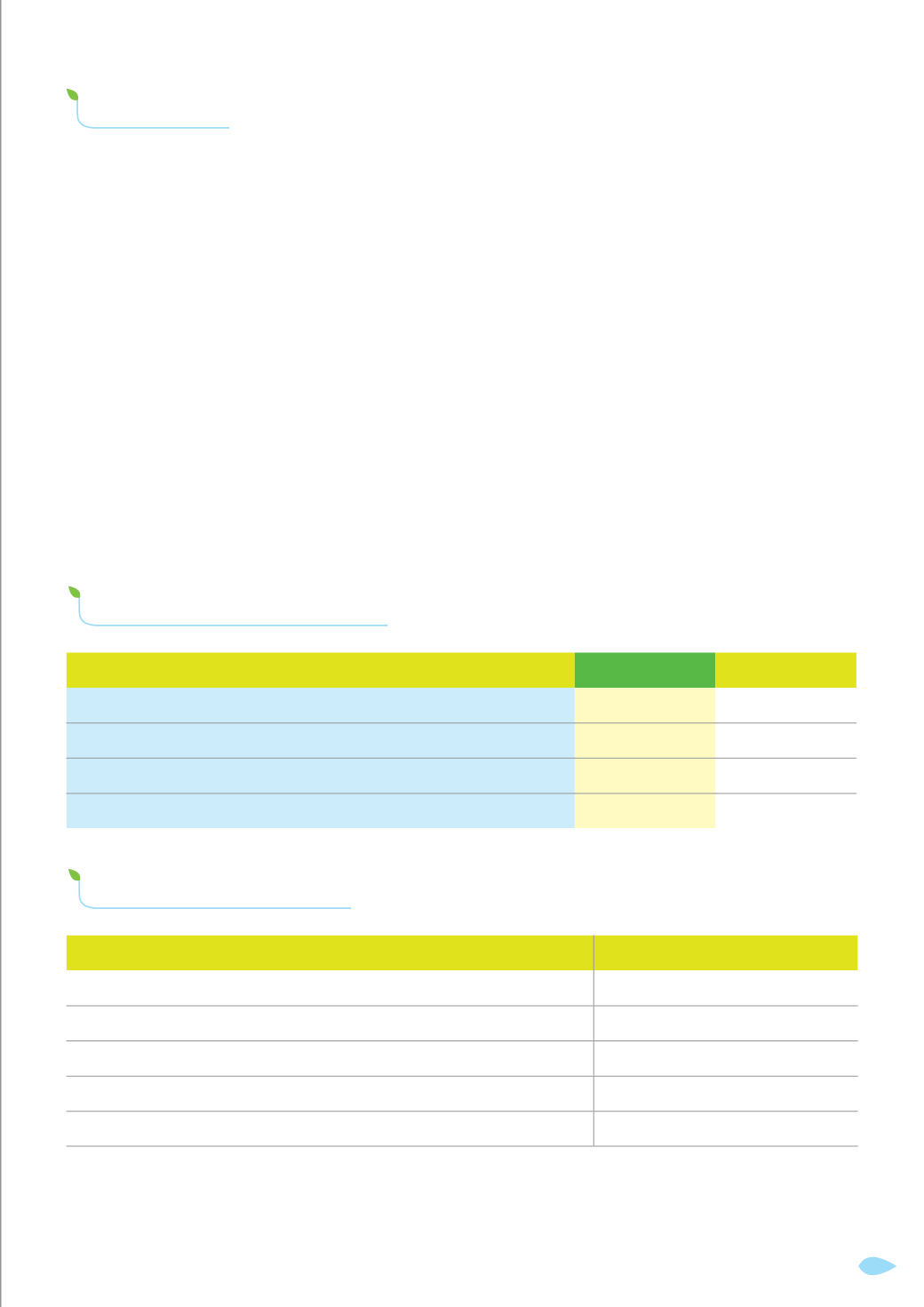

Type of Pipeline

Frequency of Leakage Surveys

All HP & IPB Mains

At least once a year

Medium-pressure Ductile Iron Pipes or All-galvanised Iron Pipes

At least six times a year

Low-pressure Ductile Iron Pipes

At least three times a year

PE or Steel Pipes Over or Enclosed within Structures

At least twice a year

Others

At least once a year