Sustainability Report 2012 • 27

Turning Waste into Energy

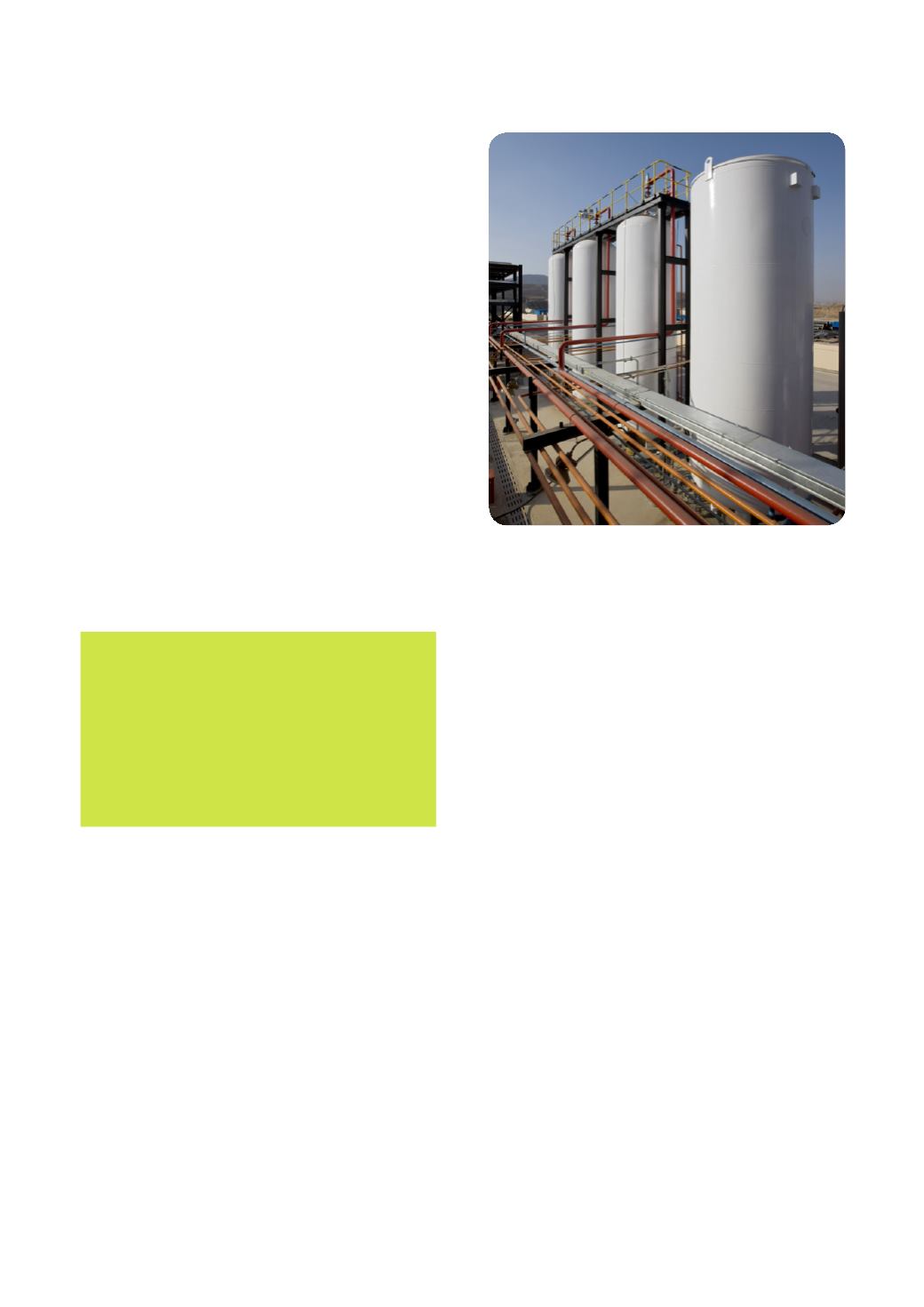

Landfill Gas

As the first organisation in Hong Kong to use

landfill gas (LFG) on a commercial basis, we are

a pioneer in the use of this “waste material”. In

1999, we began harvesting LFG from the Shuen

Wan landfill site for use as a heating fuel in our

operations. In 2007, these activities expanded to

the much larger North East NewTerritories (NENT)

landfill site, resulting in one of the largest examples

of this “green”energy recovery and reuse in the

world. Now accounting for about 2% of our total

production fuel, we expect this usage to increase

yet again when negotiations with the Hong Kong

government with regard to the utilisation of LFG

from the South Eastern NewTerritories (SENT)

landfill site are completed.

Coalbed Methane and Coal-mine

Methane Activities

Based on the experience gained in the use of

LFG, we have commissioned China’s first large-

scale coalbed methane (CBM) liquefaction plant

in Shanxi province. CBM, a natural gas found in

coalbeds, like LFG, was traditionally considered

a waste material and flared off on site. However

using cryogenic technology developed in

conjunction with a research institute, our

liquefaction plant converts the purified CBM into

liquid form by freezing it to -162 degrees Celsius.

The resulting liquefied coalbed methane (LCBM) is

600 times more concentrated in energy intensity,

making it easily transportable by road tankers

to wherever it is needed. The first tankers began

to roll out in December 2008. With the opening

of its phase-two facility in March 2011, it is now

operating at its production capacity of 250 million

cubic metres a year.

In view of the benefits of LCBM – it is a safe and

environmentally-friendly energy providing a

clean and quality fuel that is easily transportable,

the extraction of CBM provides a safer working

environment for miners, and it turns a highly

polluting waste material into a valuable resource

– we are exploring further opportunities in this

market. In Guizhou province we have conducted

an innovation test with promising results on

surface extraction of CMB for coal mines of low

permeability.

The use of LFG not only reduces the

release of greenhouse gases into

the atmosphere – it currently saves

41,000 tonnes of carbon emissions

a year and conserves around 13,400

tonnes of naphtha annually.