42 • Sustainability Report 2012

These activities and efforts are aided by the most

up-to-date equipment and technology – during

the year for instance our field staff began using

tablet computers to keep in touch with the office.

With their GPS function they not only pinpoint

the exact location of the problem, they are also

able to send instant photos from the site to our

management and operational systems. Further

innovations included the introduction of a new

Ovality Measurement Tool which enhances the

quality of PE fusion joints; the Laparobot which

removes dip pipes in condensate receivers in the

older metallic network; as well as the “Predator”

which uses infra-red thermography to locate

leakage points in underground piping. All three

inventions were developed in-house and are the

first of their kind in the world.

During the year, we received a reminder of the

need for constant vigilance and the ability to

respond quickly in the face of an emergency. In

early June, water leaked into our pipelines due

to the bursting of a water main in the vicinity,

resulting in a number of our customers in Tai

Po lost service. Working around the clock, most

customers were back on line the next day and

everything was back to normal in 56 hours.

Our wholly owned subsidiary, Quality Testing

Services Limited (QTS) is accredited under the

Hong Kong Laboratory Accreditation Scheme

(HOKLAS) for its gas meter calibration services as

well as the testing of gas appliances and stainless

steel flexible gas tubing. Our “Pay-for-Safety,

Quality and Environmental Appraisal System” also

encourages both contractors and their staff to

behave responsibly in our pipelaying contracts,

with contractors receiving 1-2% of the contract

sum if they meet specified criteria. Under this

initiative, 50% of the incentive payments are paid

to the frontline workers themselves.

Area

Achievement

Target

Gas Supply Reliability

99.996%

>99.99%

Emergencies attended to within 30 minutes

97.7%

>95%

Public Reported Gas Seepage incidents per 10km of gas pipes

0.18

<0.215

Third Party Damage incidents

12

<12

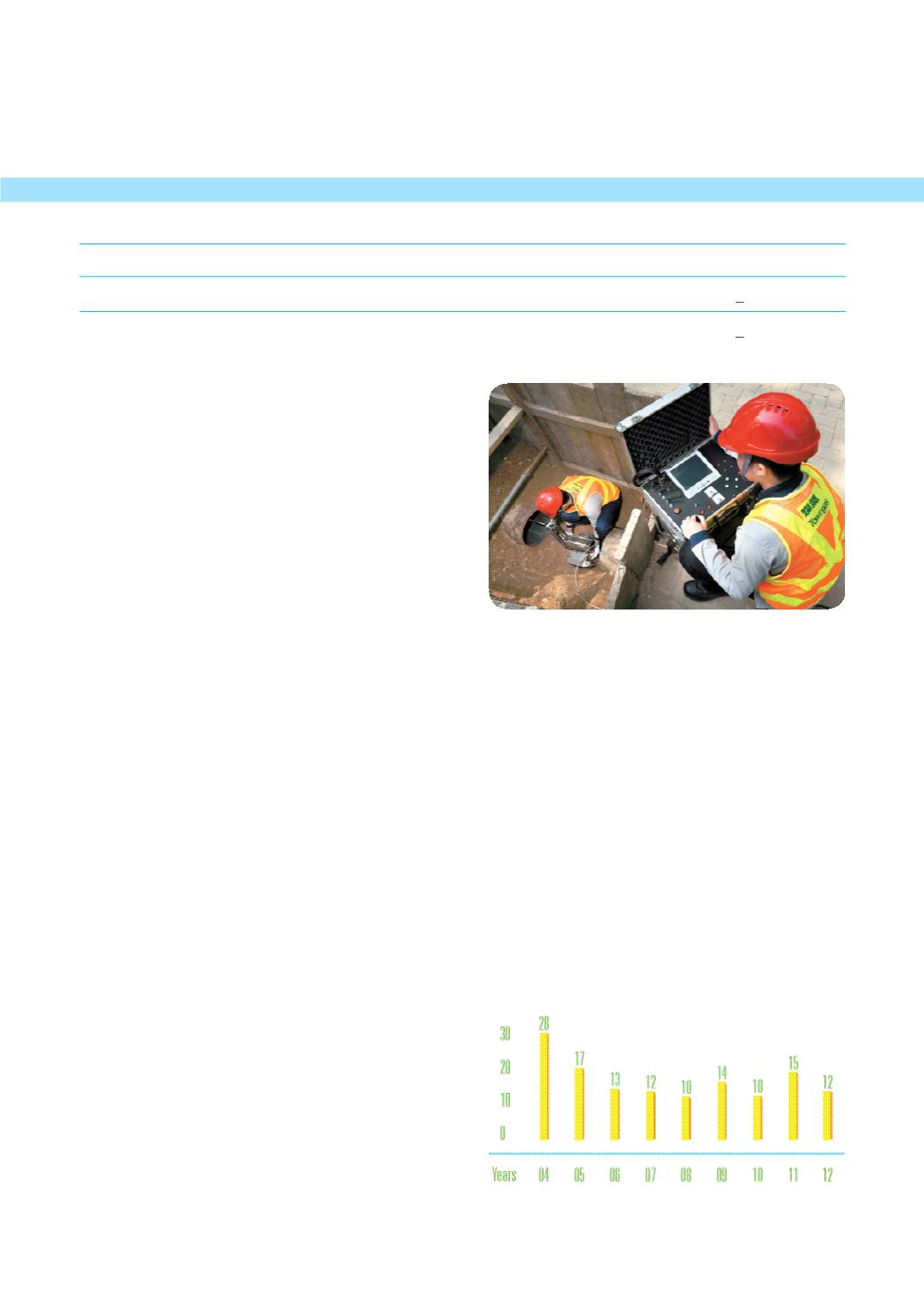

Network Safety

Number of Third Damage Incidents